Introduction

When sourcing products from Chinese factories, maintaining quality control is paramount. The Acceptance Quality Limit (AQL) standard serves as a critical tool in this regard, helping buyers establish quality expectations and streamline inspection processes. In this article, we’ll delve into how the AQL standard works, why it’s essential, and how to utilize it effectively to optimize your procurement experience.

How Does AQL Work?

The AQL standard consists of two tables designed to guide inspectors on the quantity of products to inspect and when to accept or reject production. Its primary purpose is to manage defects in a batch of products based on client-defined quality expectations.

Why Use the AQL Standard?

The AQL standard, particularly the ANSI ASQ Z1.4 version, offers several advantages:

- Limits Waste: AQL minimizes waste by specifying the number of products to inspect and the allowable defects. This helps maintain a clear understanding of the quality level without unnecessary testing.

- Reduces Time and Cost: Inspecting 100% of a production batch can be time-consuming and expensive. AQL strikes a balance between ensuring quality and managing inspection costs. Inspecting every unit may lead to increased expenses and production delays.

- Adapts to Order Size: AQL inspections are more flexible than fixed-percentage inspections. They provide equally reliable results without the need to inspect an impractical number of products for large orders.

Components of AQL

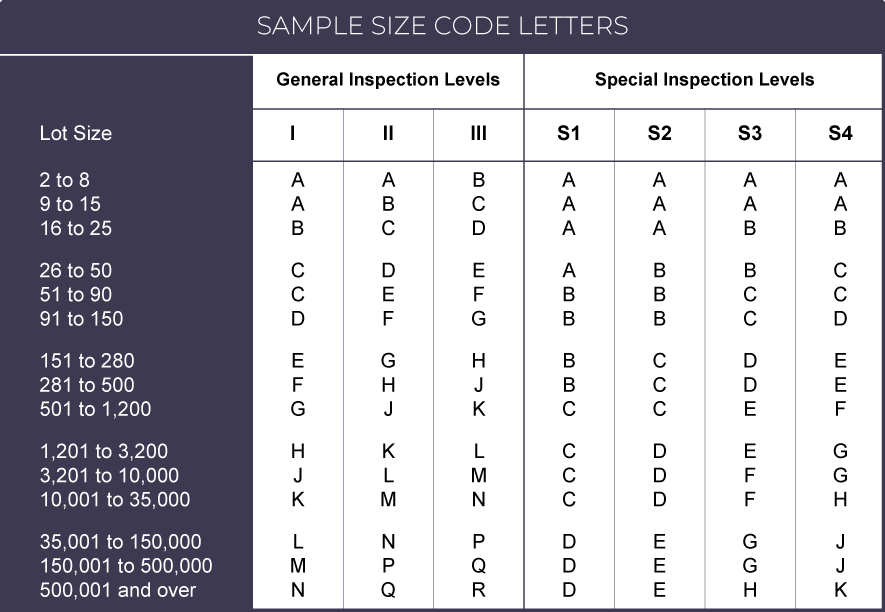

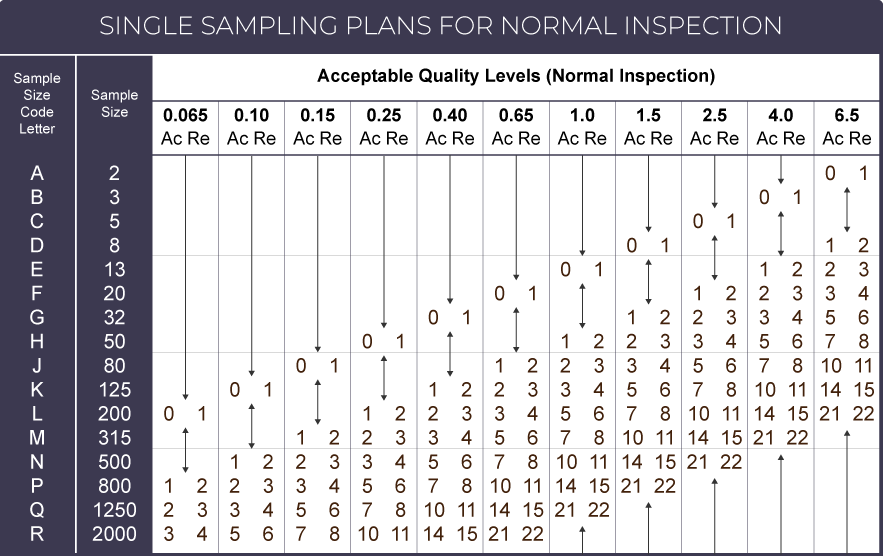

AQL is composed of two tables: “Sample Size Code Letters” (Table A) and “Single Sampling Plans for Normal Inspection” (Table B).

- Table A: Setting the Sampling Size

- Lot Size: Define the lot size as the quantity of your order for a specific product. Different products should be considered as separate lots. Find your order quantity range on the table.

- General Inspection Levels: Choose a general inspection level (I, II, or III) based on your budget and risk tolerance. Level II is commonly used for inspections in China.

- Special Inspection Levels: These are for tests or procedures that don’t require inspection of the entire sample size, resulting in smaller sampling sizes.

- Sample Size Code Letter: The letter indicates the sampling size, ranging from A (smallest) to R (largest batch).

- Table B: Collecting Accepted and Rejected Quantities

- Sample Size: Refers to the sample size determined by the code letter from Table A.

- Acceptance Quality Levels (AQL): Defines the maximum percentage of goods with a particular defect type that you’re willing to accept. For instance, you might accept a maximum of 1.5% of products with a specific defect, denoted as AQL 1.5.

- AC (Accepted Defect Quantity): Indicates the quantity of defects you can accept.

- RE (Rejected Defect Quantity): Represents the quantity of defects at which you can reject the entire order.

- Vertical Arrows: Guide you to the recommended “AC” and “RE” values if your sample size and AQL aren’t directly provided in the table.

Defining AQL Checkpoints

Before mass production begins, it’s crucial to establish a comprehensive list of checkpoints, specifying the quality requirements and defect tolerances. These checkpoints encompass various defect categories, including minor, major, and critical defects.

- Minor Defects (AQL 4): Generally, these defects don’t result in product returns but should be minimized.

- Major Defects (AQL 2.5): Products with major defects could lead to returns but don’t pose safety risks.

- Critical Defects (AQL 0): Critical defects violate regulations or pose safety threats and should be avoided entirely.

AQL’s Limitations

While AQL is effective for managing appearance defects (e.g., size and color), it doesn’t provide a complete picture of overall quality. It does not encompass:

- On-site Tests: Functional, safety, and performance tests.

- Regulatory Compliance: Meeting specific regulations and distributor requirements.

Therefore, it’s essential not to rely solely on AQL results but to consider the final inspection report provided by the inspection company.

Conclusion: AQL to Quality Control

The AQL standard is a valuable tool for maintaining quality control in Chinese manufacturing. While inspection companies often advise on the best inspection method based on your requirements, it’s crucial for buyers to provide a comprehensive checklist of checkpoints and defect categories early in the process. AQL offers an objective means to assess order quality while keeping costs manageable. By mastering AQL standards, buyers can enhance their procurement processes and ensure the products they receive meet their expectations for quality and performance.