Introduction

In our practice of supply chain operation, Six Sigma DMAIC is a crucial methodology for efficient and effective management. Let’s embark on an exploration of these concepts, weaving through their intricacies. This blog is referenced from www.sixsigma-institute.org only for information-sharing purposes.

What is Six Sigma

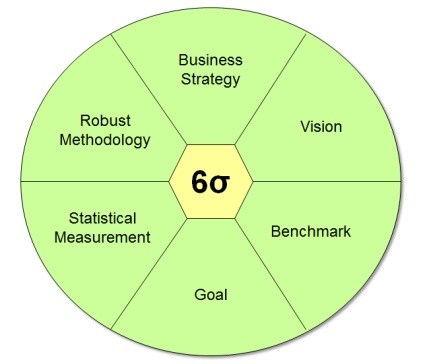

Picture Six Sigma as a seasoned guide, leading businesses towards a utopia of operational excellence. It’s not merely a strategy; it’s an unspoken commitment to precision, quality, and defect-free processes. But what exactly is Six Sigma beyond the buzzwords?

A Vision and Benchmark: Beyond being a statistical measure, Six Sigma becomes a visionary compass. It’s a benchmark, a goal, and a robust methodology for problem-solving, ensuring that every process is a step closer to perfection.

What is DMAIC

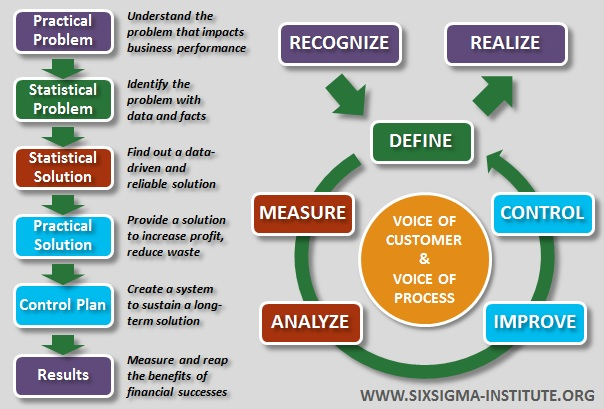

Now, enter DMAIC – Define, Measure, Analyze, Improve, and Control – the harmonious notes that play a crucial role.

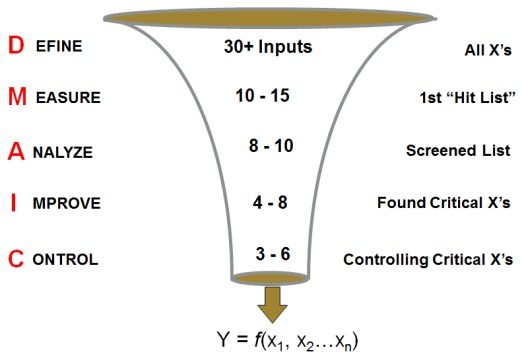

Define: In the Define phase, we validate business opportunities, shaping a vision for defect-free processes. The voice of the customer takes center stage, setting the tone for what follows.

Measure: Precision becomes an art in the Measure phase. We meticulously identify project goals, craft data collection strategies, and validate measurement systems, ensuring that every data point is a step towards insight.

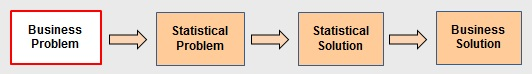

Analyze: The Analyze phase is where we dive into the intricate nuances of project elements. Statistical validation, a detailed business process map, and prioritized data collection become the tools for navigating through the labyrinth of variables.

Improve: In the Improve phase, innovation becomes our companion. Potential solutions are generated, failure modes assessed, and feasibility becomes the yardstick for change. Our journey is not just about improvement; it’s about fostering sustainable, efficient transformations.

Control: Control is the final movement in this symphony. We execute meticulous control plans, ensuring that the achieved standards persist. It’s not just about concluding a project; it’s about embedding excellence into the DNA of operations.

How Does Six Sigma DMAIC Process Work

To learn more about how Six Sigma DMAIC Process work, please feel free to check out this website: https://www.sixsigma-institute.org/How_Does_Six_Sigma_DMAIC_Process_Work.php

Learn more about Six Sigma

Explore and learn more about Six Sigma through these amazing sites:

– History of Six Sigma: https://www.quality-assurance-solutions.com/History-of-Six-Sigma.html

-What is Six Sigma? https://www.indeed.com/career-advice/career-development/six-sigma-certifications

-Benefit of Six Sigma: https://www.greycampus.com/blog/quality-management/six-sigma-certification-how-does-it-benefit-your-career-and-organization

-What is Lean Six Sigma: https://leansixsigmagroep.nl/en/lean-agile-and-six-sigma/what-is-lean-six-sigma/

– Six Sigma Belts: https://certificationacademy.com/six-sigma-belt-levels-explained/

Conclusion

Fitsbuy’s journey with Six Sigma and DMAIC isn’t just a methodology; it’s a commitment to precision, quality, and innovation. As we offer this glimpse into our practices, we warmly invite you to explore further and witness how every process at Fitsbuy is a testament to excellence. Get in touch today